FEATURED PRODUCTS & SYSTEMS

INDUSTRY HIGHLIGHTS

Montville Facility Embraces Septage...

View

A Connecticut Clean-Water Plant Turns Septage Into a Revenue-Generating Asset with...

View

When a Creamery Closed and Left His Town’s Clean-Water Plant Short of Revenue......

View

New Treatment Plant Allows Sought-After Southside to...

View

Booming Bentonville Continues to Put the Best ...

View

Upgraded Aerators and New Headworks Equipment Help...

View

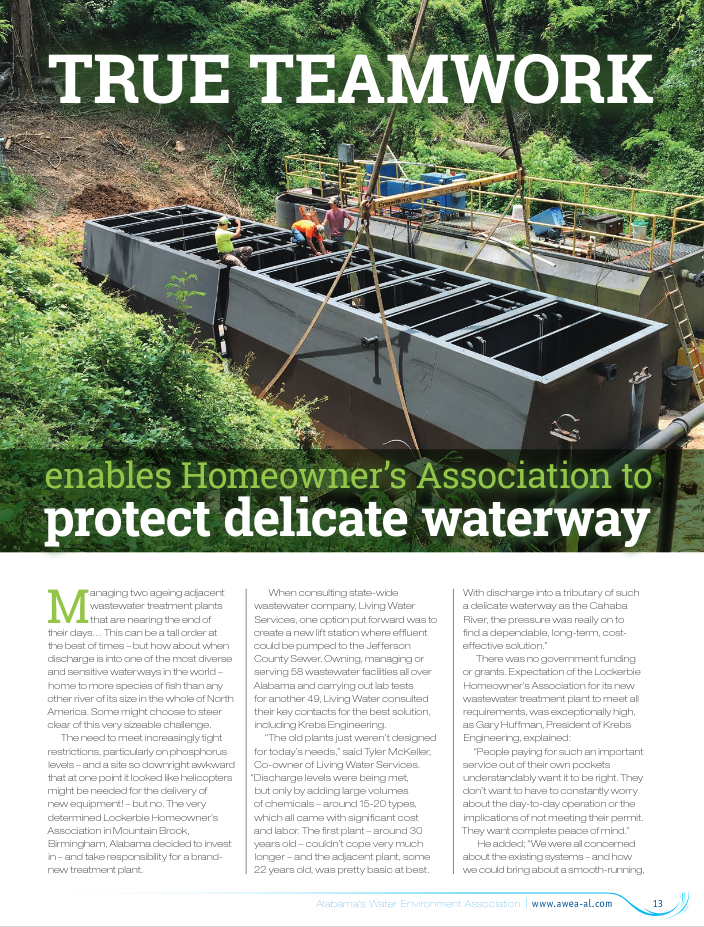

True Teamwork Enables homeowner's Association to Protect ...

View

Fine Screen and Clarifier Play Vital Role in Addison WWTP...

View

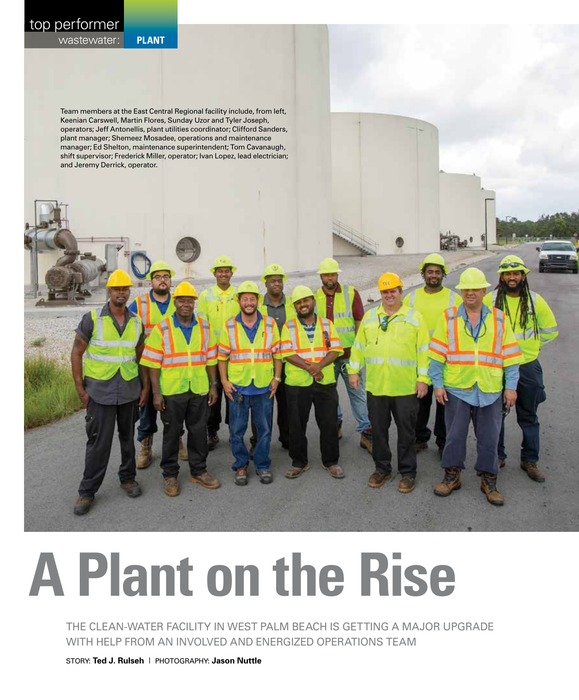

Clean-Water Facility in West Palm Beach is Getting a...

View

Robust Grit Removal System Helps Florida Facility Treat ...

View

Georgia Treatment Plant Gets Long Life From it's Influent...

View

An Efficient Fine Screen and a Peripheral-Feed Clarifier Play Important ...

View

Phased Control Allows Lake Wales to Achieve ...

View

Milton Regional Sewer Authority is Working on ...

View

WHAT OUR CUSTOMERS ARE SAYING…

“We literally just let the Lakeside Fine Screen run and it does its job. With our previous system, we were tearing apart the pumps up to three times a week to clear out the materials plugging the pumps. You have no idea how much easier our jobs have gotten since we added the Raptor Fine Screen.” — Plant Operator, WWTP