Flowmaker Propeller Mixers and Pumps

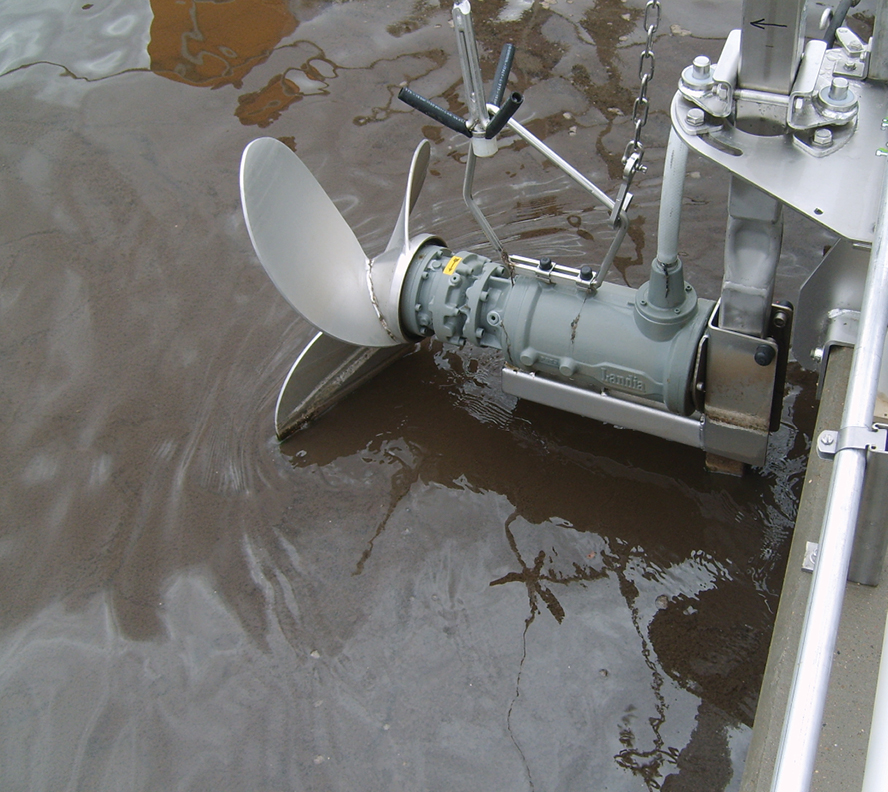

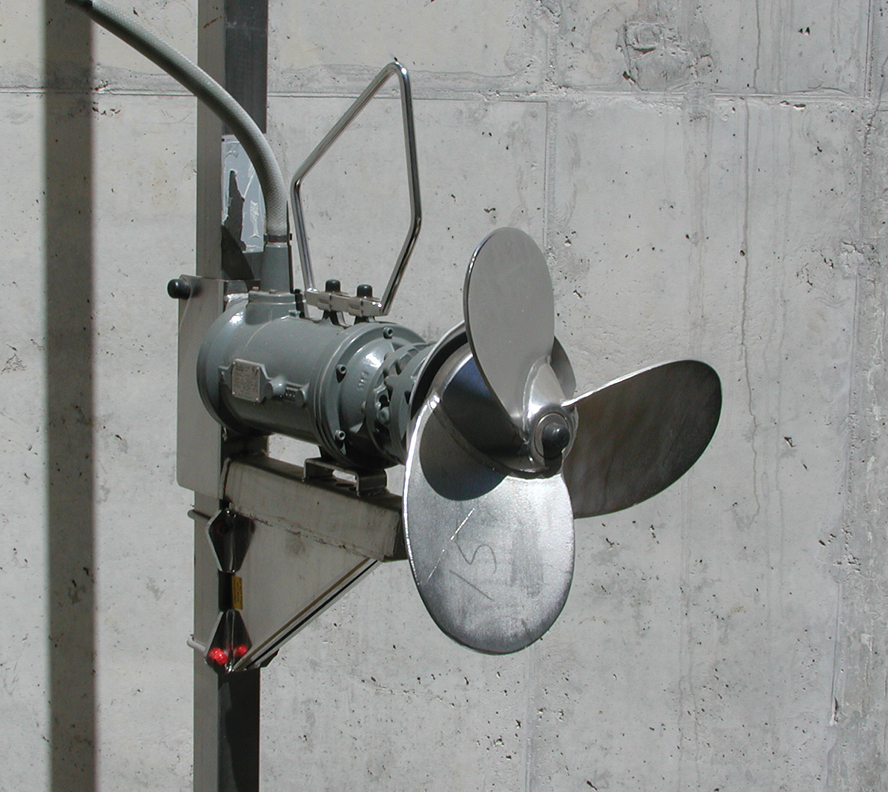

Submersible mixers and recirculation pumps are an excellent complement to the Sequencing Batch Reactor (SBR) and Closed Loop Reactor (CLR) Process that are designed for Biological Nutrient Removal (BNR) applications or energy conservation. The mixers and pumps have a stainless steel propeller that is shaped for optimum flow and a highly efficient planetary drive resulting in low energy consumption.

Low and medium speed submersible mixers are used to thoroughly mix the contents in the anaerobic tank, anoxic tank, or CLR aerobic reactor. This helps reduce power costs in low flow start-up conditions, where oxygen requirements are well below the mixing needs. In denitrification applications, the submersible mixer and aeration are cycled to provide anoxic and aerobic conditions within the SBR or CLR reactor for total nitrogen reduction.

Recirculation pumps are provided in denitrifcation applications to recycle mixed liquor from the aerobic basin back to the anoxic stage. The recirculation pumps are designed for high efficient pumping of large quantity of liquid at low head, which makes it ideal for BNR processes.

Advantages

- Highly efficient planetary gear system resulting in low energy consumption

- Stainless steel propeller designed for optimum flow

- Mast systems available with multiple mounting and adjustment configurations