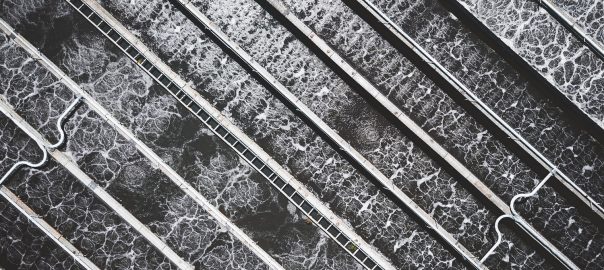

Wastewater treatment plants are there to clean and purify water that arrives through sewer lines, septage haulers, etc. The process removes bacteria, solids, and other impurities until the water is clean enough to go back into the district’s water supply or get released into area bodies of water.

What about pharmaceuticals? Can wastewater treatment plants remove pharmaceuticals before the water returns to public water sources, lakes, streams, and other water sources? Studies show that many drugs end up in treated water even after a normal treatment process.

Wastewater Treatment May Not Remove Everything

In a month’s time, it’s estimated that close to 46% of Americans have taken at least one prescription drug. As you get older, chronic health conditions are more likely. Around 85% of American’s aging adults (60 or older) take medications daily. Adults aren’t alone. It’s found that about 18% of children 12 or younger take at least one prescription medication.

You probably take vitamins, herbal remedies, over-the-counter meds, and/or prescriptions on a daily basis and never stop to think about the impact they have on wastewater. Pharmaceutical plants and the liquid manure from livestock treated with veterinary pharmaceuticals that gets spread on fields aren’t the only cause of these compounds getting into groundwater and streams.

The reality is that the medications people take also find their way into your wastewater. They’re excreted through fecal matter and urine or expired or unneeded pills are flushed down drains or toilets. The wastewater treatment process does what it can to remove them. The problem is that water treatment can’t get all of the drugs out of the water.

A study looked at the wastewater from 50 of the nation’s wastewater treatment plants. Pharmaceuticals were found in all 50 samples. Valsartan (blood pressure medication) had the highest levels, but atenolol (blood pressure), carbamazepine (epilepsy), and metoprolol (heart/beta-blocker) were also found in high levels. While it’s uncertain the levels remaining after the water is cleaned is dangerous to humans, questions arose as to whether the drugs would harm aquatic animals.

In 2020, a University of Cincinnati biologist decided to look at the effects of estrogen (birth control pills) on freshwater fish. As estrogen had been found in streams near wastewater treatment plants, the study looked to see what would happen if native fish were exposed.

In the study, the researchers focused on a native fish that has live births rather than lay eggs. They put them in fresh water that contained a controlled level of estrogen. The fishes’ fertility was affected and fewer babies, especially males, were born to the fish in the study. The shocking thing is that the researchers had used levels of estrogen that were 16 times lower than was found in the streams.

Many people today take antidepressants. How well is wastewater treatment removing antidepressants? Researchers took a look at the tissue of fish found upstream from two wastewater treatment plants in Colorado and Iowa. Fish found upstream showed no signs of antidepressants.

They also collected fish five miles downstream of where the same wastewater treatment plants were releasing treated water. Those fish had noticeable levels of common antidepressants like fluoxetine (Prozac) and sertraline (Xanax). The water samples also tested positive for containing those and bupropion (Wellbutrin), citalopram (Celexa), and venlafaxine (Effexor XR).

What about antibiotics? One of the first was penicillin, but science advanced and many of today’s antibiotics are synthetics like sulfonamides or semi-synthetics like amoxicillin. A study of water within the Great Lakes found that wastewater contained several pharmaceuticals including two antibiotics.

So many medications are being found in water that’s been treated and released to streams, rivers, lakes, and ponds. They’re making their way into the oceans. It’s shown that the drugs can impact fish, mammals, crustaceans, shellfish, and other aquatic creatures.

Federal Regulations on Wastewater Treatment Don’t Cover Pharmaceuticals

The Federal Government maintains a list of chemicals, metals, and other contaminants that must be removed from wastewater before it’s released. Pharmaceuticals are not on that list. While attention is being raised, only four compounds found in pharmaceuticals for human use are even being considered. Three of them are in birth control pills and one is an antibiotic.

This is concerning as a 2007 study tested for 17 different pharmaceuticals in samples taken from 20 different municipal water systems. More than 50% of the water samples tested positive for carbamazepine (anticonvulsant), ibuprofen (NSAID pain reliever), iopromide (contrast agent for scans of the body), meprobamate (tranquilizer), and phenytoin (anticonvulsant).

A second in-depth study went back and found meprobamate and phenytoin in 50% of the samples. While the levels were too low to impact humans, it does raise concerns on how these medications affect fish and other aquatic creatures.

Many wastewater treatment plants are already removing pharmaceuticals, but only a percentage is removed through typical wastewater treatment plans. There’s still a percentage making it into the water. Which leads to the question of what else can be done.

What Steps Help Remove Pharmaceuticals?

How well wastewater treatment removes pharmaceuticals depends on what system a district uses. Activated sludge is one of the more common treatment processes. It uses microorganisms to break down contaminants. It’s not overly effective on pharmaceuticals. Dr. Diana Aga, a chemistry professor, says more pharmaceuticals would be removed if wastewater treatment plants paired activated sludge with granular activated carbon filters.

What steps in water treatment help remove the medications people take? A study looked at the different water treatment steps and whether or not they were partly effective at removing certain medications.

- Anabolics/Steroids – Reverse osmosis was most effective, but nanofiltration, ozonation, and granular activated carbon was also useful.

- Antibiotics – Ultrafiltration with powdered activated carbon and reverse osmosis were effective.

- Carbamazepine (Anticonvulsant) – Ultrafiltration with powdered activated carbon and reverse osmosis were the most effective treatment methods.

- Diazepam (Sedative) – Reverse osmosis was the most effective with ultrafiltration using powdered activated carbon as a second-best choice.

- Diclofenac and Ibuprofen (NSAID) – Reverse osmosis and soil aquifer treatments were the best options, and granular activated carbon filters also worked well on

- Paracetamol (Tylenol) – Ozonation and reverse osmosis were the most effective ways to remove this pain reliever from wastewater.

There is a lot of evidence in filtration being the best way to remove pharmaceuticals. Your wastewater treatment plant can help get pharmaceuticals out of the wastewater that’s treated and released. What is your plant’s design? Have you set up a system that pairs activated sludge with some form of carbon filtration? Maybe it’s time to consider a change that helps keep pharmaceuticals out of the water while also improving your plant’s expenditures.

Is it time to upgrade your wastewater treatment equipment? If you’re looking to clean wastewater effectively and efficiently, modernizing some equipment can help improve your plant’s performance while lowering electricity costs. Your district saves money, which makes everyone happy.

Lakeside Equipment has been a leader in water purification for close to a century. Talk to us about our Learn more about the steps to take for cleaner water and lower energy costs.