The wastewater you treat contains more than organic materials. Cinders, gravel, sand, and other heavier solids are also found in wastewater. This grit must be removed if you’re going to prevent clogged piping and abrasive damage to the equipment. If grit isn’t removed, it moves on to aeration tanks and digesters where it impedes the treatment process.

Grit Removal Methods

You have wastewater to clean and grit removal is one of the first steps towards clean water. What are your options? Several methods are available for grit removal. Take a look at the options you’ll encounter when discussing the equipment for your water treatment plant.

Aerated Grit Chambers

In an aerated grit chamber, air is pumped in on one side, which forces incoming wastewater into a spiral flow. As the water flows, the heavier grit falls to the bottom of that tank while lighter organic materials and water continue to the exit. Energy use is higher with an aerated grit chamber. Maintenance costs can also be higher in this type of system.

Detritus Tanks

Detritus tanks are square in design and have to be followed with grit washing to remove the organic materials that get trapped in the grit that’s removed. Augers and rakes are typically used to remove the grit, which means electricity will be running and driving up energy consumption. The rake arm can also agitate the wastewater and stir up some grit and lead to some of it escaping as wastewater flows out. It’s also harder to control flow rates when you use a detritus tank.

Horizontal Flow

Horizontal flow grit chambers are one of the older types you’ll come across. Wastewater enters the horizontal chamber and flows through several small dam-like areas (weirs) that trap grit while the water keeps moving from one area to the next. Grit is removed using scrapers. Flow rates can be harder to control with this system, and headloss is also a concern. The equipment may wear faster, too.

Hydrocyclones

Hydrocyclone systems find wastewater being pumped into the grit chamber and the cyclone force traps the grit and solids on the sides and bottom where they’re removed. The benefit is that both grit and solids are removed at the same time. If you do not screen wastewater before the grit removal process, the hydrocyclone system will run into issues with solids like plastics, rags, and sticks.

Stacked Trays

Some water treatment plants use stacked trays. This system has several trays stacked in a round chamber. Water comes in at the top and circulates over each of these trays. Grit falls to the bottom chamber while the water flows out the other side. Grit is then removed from that lower chamber. While stacked tray systems do not always need electricity, they can be cost-effective, but the depth of the system requires excavation that can be costly. Headloss can also be a concern.

Vortex Systems

Vortex grit removal technology may seem similar, but it’s not. There are differences in technology that you need to consider to ensure you’re getting optimal grit removal and efficiency. One area where vortex grit removal is similar is that wastewater flows into a circular tank. With that tank is a mechanical rotor that creates a vortex that can slow down or speed up depending on flow rates.

Paddles rotate to stabilize the flow velocity. This keeps organic particles suspended within the wastewater while heavier particles of grit sink to the floor. At floor level, the vortex pushes grit to the center where it moves into a grit hopper. From there, it travels to the grit classifier by being pumped, airlifted, or pushed out through an impeller. Grit is washed in the grit classifier to remove any remaining organics. The final step is to move it to trucks, hoppers, or dumpsters where it goes to a disposal facility or landfill.

Vortex systems are popular due to the space that’s needed for installation, the effectiveness, and the overall cost. You should put a vortex grit chamber at the top of your list.

How Effective Are Vortex Grit Chambers?

You’ve narrowed down your choices for vortex grit removal systems. Two of the leading options are the Smith & Loveless Pista Grit Removal System and Lakeside Equipment SpiraGrit® Vortex Grit Removal System. The Smith & Loveless Pista Grit comes in several models that are capable of removing up to 95% of the grit in your wastewater. Pista Grit uses a hydraulic design with a flat chamber floor and propeller that creates the vortex. This propeller doesn’t require a lot of energy, so it can be a cost-effective grit removal system. You choose if you want the system to be baffled or not.

Lakeside Equipment’s SpiraGrit® Vortex Grit Removal System allows you to choose a few things. It’s also an energy-efficient model where it adapts to a range of daily flow rates. Paddles keep the vortex flow moving steadily, so organics float to the top while heavier grit moves downward to the bottom where it falls into a grit hopper and is pumped out using a self-priming pump, airlift pump, or impeller. At that point, you can have the grit move to Lakeside Equipment’s Grit Classifier or the Raptor® Grit Washer as the next step.

Why is the Lakeside SpiraGrit® Vortex Grit Removal System the Ideal Choice?

Lakeside’s SpiraGrit® Vortex Grit Removal System has one of the highest removal efficiencies on the market. It doesn’t matter what the flow rate is, this grit removal system does an exceptional job in a compact size. Head loss rates for the SpiraGrit® Vortex Grit Removal System are also low. You don’t need a lot of space for the SpiraGrit® Vortex Grit Removal System. It’s designed to be efficient and compact. It’s also designed to separate grit and perform dewatering at the same time, which adds to the efficiency.

If you’re worried about high maintenance costs, don’t worry. There are no submerged bearings. This grit removal system is easy to maintain. You can also have the SpiraGrit® Vortex Grit Removal System crafted from stainless steel to prevent corrosion.

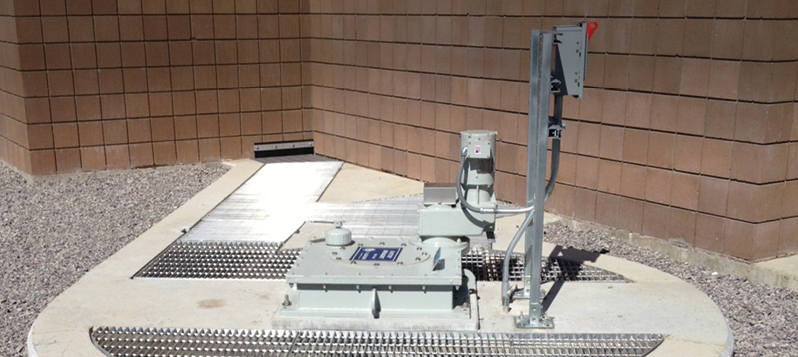

A Headworks Packaged System Covers Everything You Need

With Lakeside’s H-PAC system, you get the SpiraGrit® Vortex Grit Chamber within a full headworks system that’s capable of flow rates of up to 12 million gallons per day. Start with the Raptor® Screen that removes, washes, and dewaters items it captures on the screens. From there, the pre-screened wastewater enters the grit chamber where fine particles of grit are removed. This protects equipment used later in the wastewater treatment process.

For more than 90 years, Lakeside Equipment has provided solutions for treatment plant designers and engineers. Lakeside’s experience with water purification and water treatment processes cannot be matched. Our engineers will design a system that meets your needs and matches your budget. Our goal is to design a system that is built to last, and should you ever need parts, we have a stellar parts department who are happy to help you.

Choose Lakeside’s H-PAC® system with the SpiraGrit® Vortex Grit Chamber for a cost-effective, highly efficient grit removal system. It doesn’t require a lot of space, so you don’t have to worry about having a lot of room available for your grit removal needs. For more information on how you can achieve Lakeside quality and performance, contact one of our experts at 630-837-5640, email us at sales@lakeside-equipmnet.com or visit our website www.lakeside-equipment.com